Heavy duty diesel engines are very reliable and, if properly maintained, will last over 1 million miles. In some cases, gaskets will fail over time. For example, external coolant leaks at head to block or oil seepage are indications of a failed head gasket. When that happens, it is very important to get your truck to an appropriate shop to diagnose possible causes.

There are several symptoms seen with a failed head gasket. External leakage of any fluids at the meeting surface of the head and the block can be a visual confirmation of a failure. As mentioned before, it is very important to have the right shop troubleshoot the issue. Many times, a leak could be from another source and leakage can run down the engine, giving a false reading. It is always a good practice to clean and run the engine to verify where any leaks are coming. If the external leak is coolant, then the cooling system must be pressurized to verify the source of that leakage.

In some cases, a failed head gasket can cause combustion gasses to enter the cooling system. In these cases, coolant leakage moves from the de-gas bottle due to overflow. It is best to verify the pressure entering the cooling system is caused by combustion gases by using the correct tools. In some cases, a failed air compressor can introduce unwanted air into the cooling system, leading to a false diagnostic. This is another reason it is very important to have an experienced shop troubleshoot the problem.

Cross-contamination is another symptom of a failed head gasket. Daily inspection of fluids is a good practice; if contamination is evident, for example, if you noticed coolant discoloration in the de-gas bottle or rising oil levels, these could be indications of internal leakage. When cross-contamination occurs, such as coolant mixing with oil or vice versa, it is very important to take your truck to an experienced shop for troubleshooting. Immediate attention could possibly save you money on repairs. Issues that may occur if internal leaks are left unrepaired for too long are scored or over-heated bearings. The engine’s cam, crank and piston rods depend on well-lubricated bearings when in operation and these components depend on oil to lubricate them properly and to prevent unnecessary wear. When coolant mixes with oil, the oil is unable to keep engine bearings properly lubricated, which can cause damage to those bearings and shorten the life of the engine.

In summary, head gasket failure can be identified in several ways but it is very important to have your truck checked out by an experienced shop. It is also good to have the engine head completely checked after being removed at the head shop; technicians can look for any cracks or issues that could cause a reoccurrence of failure once reassembly is complete. If a failure has been found on the head, it is best to replace or rebuild it before reassembly.

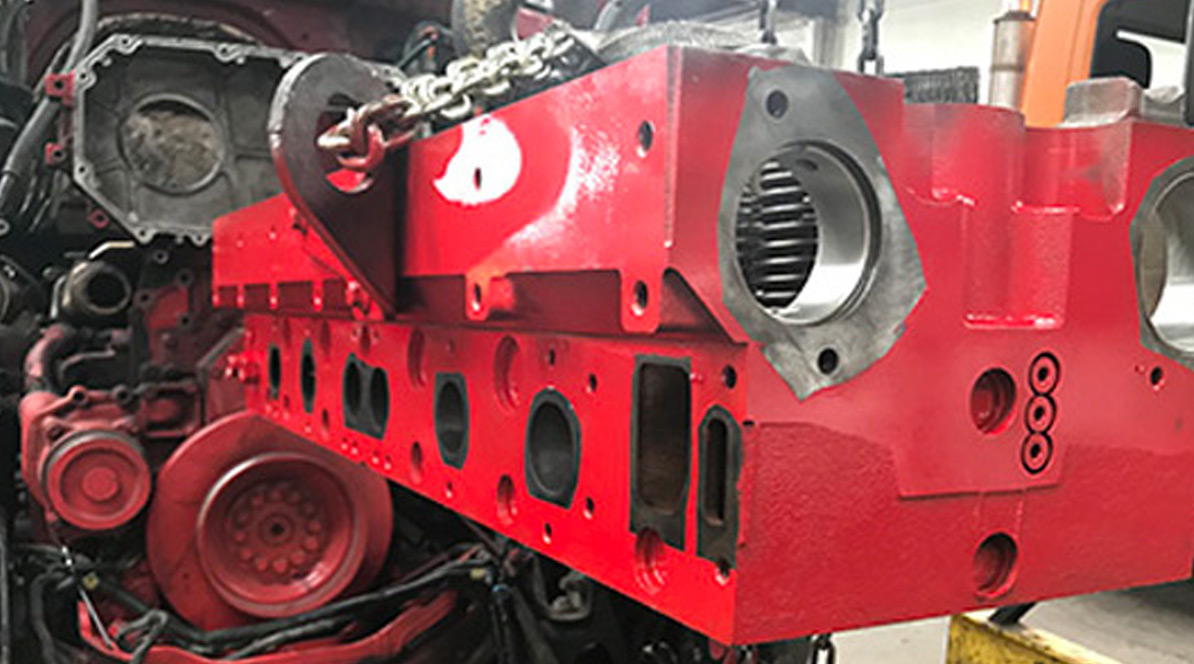

Cummins ISX Head Gasket

Cummins ISX Head Gasket

Cummins ISX Head Gasket Replacement

Cummins ISX Head Gasket Replacement

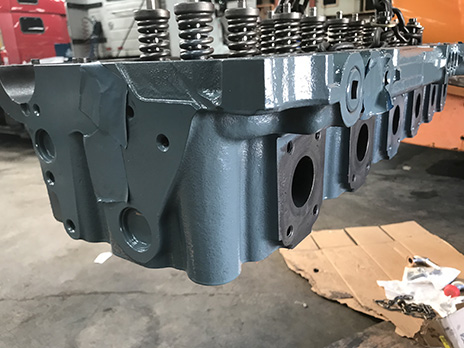

Detroit 60 Series Head

Detroit 60 Series Head

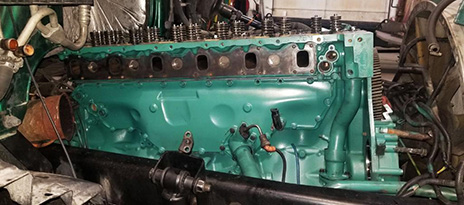

Volvo D12 Head Replacement

Volvo D12 Head Replacement

Volvo D12 Headjob Rebuild

Volvo D12 Headjob Rebuild

Volvo D12 Head Gasket Replacement

Volvo D12 Head Gasket Replacement

Detroit DD15 Head Gasket Leaking

Detroit 60 Series Head Gasket Replacement

DD15 Head Gasket

DD15 Head Gasket

Main Bearings

Main Bearings

Main Bearings Scored

Main Bearings Scored

Exhaust Coolant

Exhaust Coolant